Published July 08, 2021

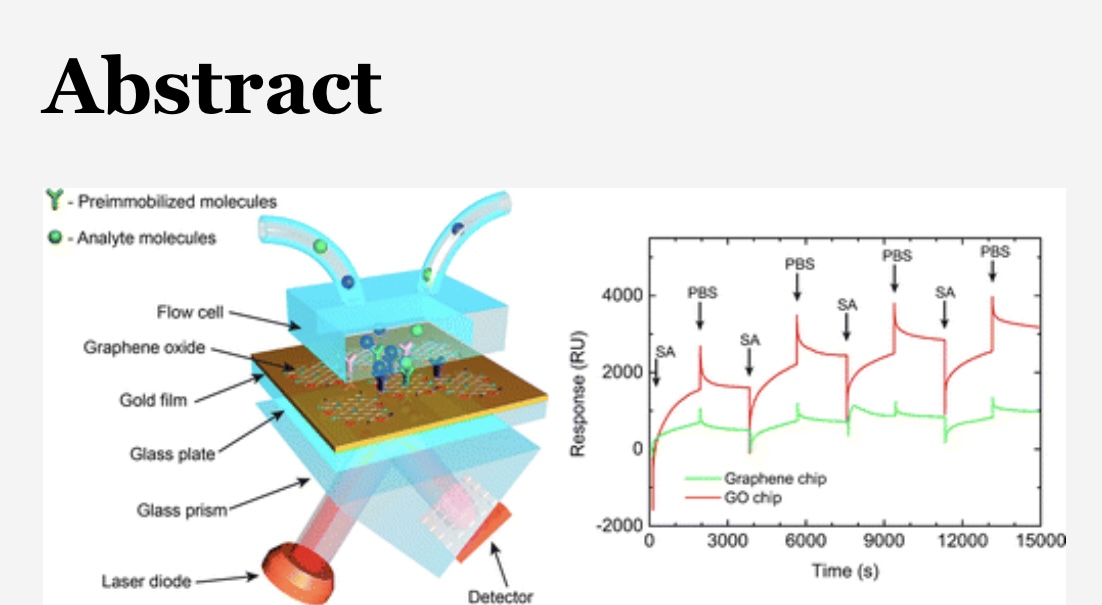

MIPT scientists have created a graphene biosensor.

The results of the study are published in the journal ACS Applied Materials and Interfaces (Stebunov et al., Highly sensitive and selective sensor chips with graphene-oxide linking layer).

http://pubs.acs.org/doi/abs/10.1021/acsami.5b04427

The label for the Internet of Things is used and widely used. All technologies developed by the company and have been promoted through SputnikGroup since 2013.

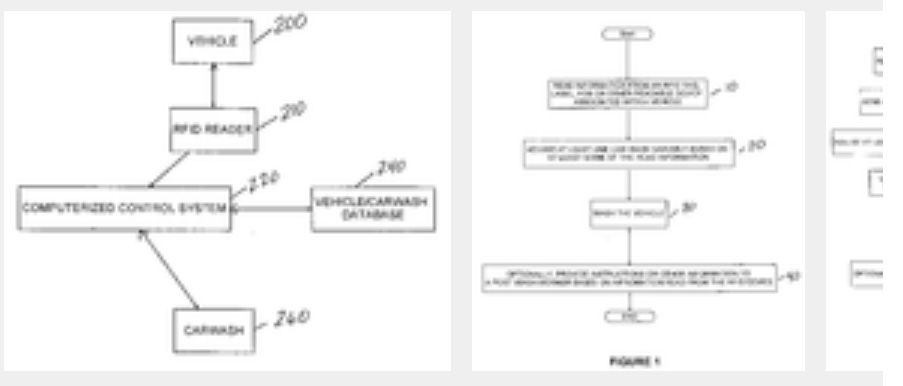

The chip itself is similar to this – the official documented. The patent, codenamed WO/2020/060606, was registered on March 26, 2020.

The issue was in the antenna of the chip – it was solved by magnetofecification.- Ginsburg is a partner of the British firm SputnikGroup since 2013 and produces its goodness from their components.

The first RFID tags were created in the 1940s and patented in the 1980s. RFID tags are able to identify physical objects and track their movements. Hence another name for labels – transponders. You can apply certain information to the RFID label, save it, and later count it.

The label consists of two parts: an antenna and a microchip. The microchip is responsible for storing the data that is recorded on it. To help write the information on a chip or count it, you need an antenna that connects the label and the reader. Without a reader, the label will not be active: there are devices that only record or read the information, and there are those that cope with both tasks.

China 🇨🇳 and their mask with Chinese snot (Figure 1)

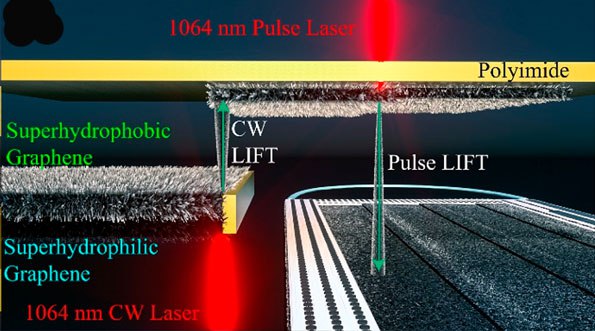

The authors of this work synthesized graphene by the effects of laser radiation on polyimide.

It is known that the correct and accurate focus of the continuous infrared laser allows you to simultaneously get superhydrophilic graphene on one surface of the polymer precursor film, and superhydrophobic on the other (Figure 2). Using the laser-induced direct transfer method lift (laser induced forward transfer), the superhydrophobic film can be transferred to the surface of another closely located substrate.

The Chinese used an IR laser with a wavelength of 1064 nm, which can work in two modes – in continuous CW (continuous wave) and in pulse. The diagram of the experiment is shown on the rice. 2. Laser Beam (1064 nm, CW) focuses on donor polyimide film. Under the influence of laser radiation is formed graphene, superhydrophobic scales of which from the surface of the donor film by lift transfer to the acceptance polyimide film (which is above at a distance of 1 mm). Next, use the same laser in pulse mode and the METHOD LIFT precipitate superhydrophobic graphene on the surface of the mask.

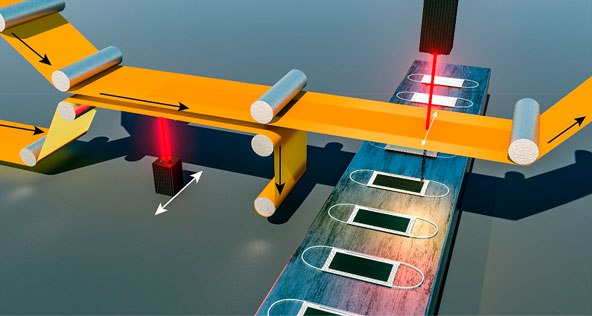

rice. 2. Formation of graphene under the influence of laser radiation: transfer of graphene to the upper polyimide film by CW LIFT and transfer of graphene by pulsed LIFT to a heat-sensitive mask.

Polyimide is an affordable precursor, a method of fusion simple, inexpensive. It was used in the production of masks on an industrial scale, using continuous laser treatment of roll film and the supply of masks on a conveyor belt, as suggested by the authors (Figure 3).

rice. 3. Illustration of the continuous production of “graphene” masks by LIFT

laser IR radiation in two modes.

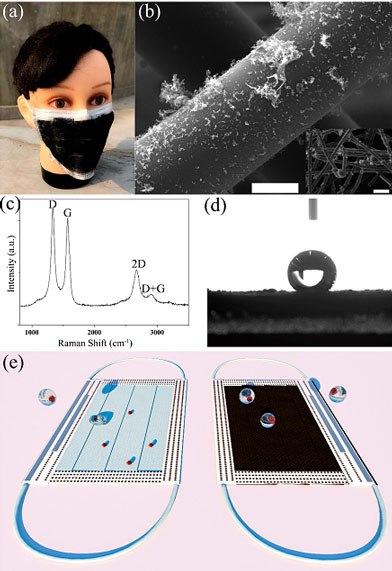

The surface of the modified mask (Figure 4a) is superhydrophobic, like a lotus leaf. This is due to the nanostructure caused by the even distribution of graphene scales on the surface of the fibers (Figure 4b).

The fact that it is really graphene, consisting of only a few layers, clearly shows the Raman spectra (Figure 4c). The edge angle is more than 140o (at hydrophobic factory mask 110o) (Figure 4d).

rice. 4. a – A photo of a modified mask;

– SEM image of the surface of the mask with graphene scales (size from 100 nm to several microns) (scale 10 microns; on the inset – 100 microns);

c – Raman’s spectrum of “graphene” mask;

d – wetting angle for water drop on the surface of a modified mask; e – the black “graphene” mask (as opposed to the factory blue) has a self-cleaning surface.

Magnetofection is a method of transfection.

https://en.wikipedia.org/wiki/Transfection

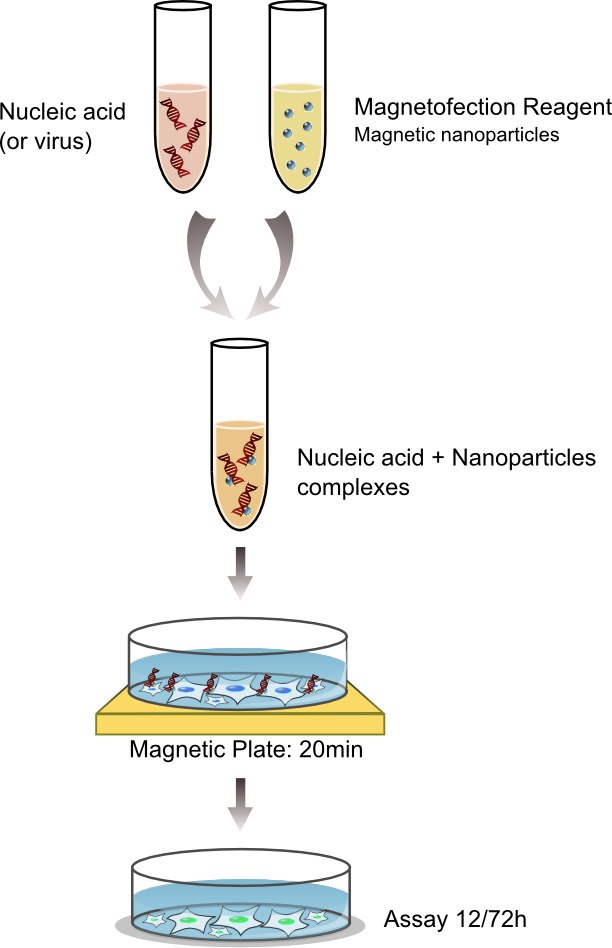

The principle of magnetoference is to bind nucleic acids, reagents for transfection or viruses with special magnetic nanoparticles. The resulting molecular complexes are concentrated and transported to cells under the influence of the corresponding magnetic field. Thus, the exploitation of magnetic force acting on gene vectors makes it possible to concentrate the entire added dose of vector on the cells very quickly, so that 100% of the cells come into contact with a significant dose of vector, and stimulates cellular capture.

Magnetic nanoparticles are made of iron oxide, which is completely biodegradable, covered with special patented cation molecules, different depending on the scope of application. Their association with gene vectors (DNA, miRNA, ODN, viruses, etc.) is achieved through salt-induced colloidal aggregation and electrostatic interaction. Magnetic particles then concentrate on cells under the influence of an external magnetic field generated by a special magnetic plate. Cellular capture of genetic material takes place due to endocytosis and pinocytosis, two natural biological processes. Consequently, the membrane architecture and structure remain intact in contrast to other physical methods of transfection, damaging, creating a hole or acting with electroshock on cell membranes. Nucleic acids are released into the cytoplasm by different mechanisms depending on the composition used:

1) The effect of a proton sponge caused by catalytic polymers on the surface on nanoparticles, which causes osmotic endos swelling, the destruction of the endosomal membrane and the release of DNA inside the cell.

2) Destabilizing endosomons with catalyte lipids on the surface of particles that release nucleic acid by flip-flop negatively charged lipids and neutralize the charge.

3) The standard mechanism for injecting nucleic acid with the virus.

BIODISTRATION OF MAGNETIC NANOPARTICLES

Biodegradable cation magnetic nanoparticles are not toxic in recommended and even higher doses. Gene vectors / magnetic complexes of nanoparticles get into cells in 10-15 minutes i.e. much faster than in any other method of transfection. After 24, 48 or 72 hours most of the particles are localized in the cytoplasm, in vacuoles (surrounded by membrane structures in cells), and occasionally in the nucleus.

Magnetophection is the only flexible and universal technology adapted to all types of nucleic acids (DNA, siRNA, dzRNA, sRNA, mRNA, ODN…), non-viral transfection systems (reactives for transfection) and viruses. In accordance with this, several optimized reagents have been developed:

LipoMag Transfection Kit: For All Nucleic Acids, CombiMag Association and DreamFect Gold Reagents

http://sputnic-group.ru/catalog/section_1385070/

MagnetoFectamine transfection kit for all nucleic acids, CombiMag combinations, lipofectamine 2000

http://sputnic-group.ru/catalog/section_1385071/

PolyMag / PolyMag Neo: reagents for transfection with any nucleic acids

http://sputnic-group.ru/catalog/section_1385072/

http://sputnic-group.ru/catalog/section_1385069/

NeuroMag transfection jet for neuron transfection

http://sputnic-group.ru/catalog/section_1385074/

CombiMag transfection reaction to improve the effectiveness of transfection reagents (see magnetofectamine),

http://sputnic-group.ru/catalog/section_1385073/

SilenceMag transfection jet for siRNA apps

http://sputnic-group.ru/catalog/section_1385085/

ViroMag transduction jet to improve viral transduction efficiency

http://sputnic-group.ru/catalog/section_1385098/

ViroMag R/L transduction react for lentiviruses and retroviruses

http://sputnic-group.ru/catalog/section_1385099/

AdenoMag transduction jet for adenoviruses and AAV

http://sputnic-group.ru/catalog/section_1385101/

Mag4C-LV /Mag4C-AD kits: to collect and concentrate lentiviruses and adenoviruses

http://sputnic-group.ru/catalog/section_1385104/

http://sputnic-group.ru/catalog/section_1385105/

FluoMag Transfection React: Fluorescent Reagents for Magnetofection

http://sputnic-group.ru/catalog/section_1385093/

SelfMag transfection kit: to create your own magnetic delivery system

http://sputnic-group.ru/catalog/section_1385115/

HOW TO USE REAGENTS FOR MAGNETOFECTION?

The protocol is a simple procedure:

1) Dilute nucleic acids or vectors in a non-whey environment or buffer and add a Magnetofection jet™.

2) Incubate for 20-30 minutes.

3) Add complexes directly to the cells.

4) Attach the magnetic field (place the petri dish on the magnetic plate).

5) Incubate for 5-20 minutes, remove the magnetic plate and cultivate the cells before analysis.

DO YOU NEED SPECIAL EQUIPMENT?

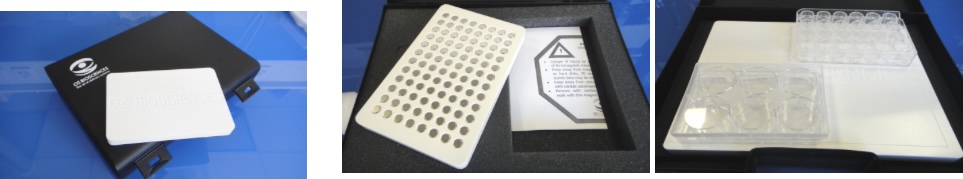

The only requirement for magnetoferection is a magnetic plate specifically designed for this method. The magnetic plate is a one-time purchase, fully reusable. Thus, you do not need expensive equipment unlike other methods such as a gene gun or electricporation. The required magnetic field is produced by special magnets. Three magnetic plates are available: a super magnetic plate, a magnetic plate with 96 individual magnets and a mega magnetic plate. Their design allows to produce a heterogeneous magnetic field, which magnetizes nanoparticles in the solution, forms a very strong gradient to attract nanoparticles and covers the entire surface of the plate. The plate can be washed 70% ethanol and used in incubators or robots.

The magnetoference technology requires an appropriate magnetic field, which magnetizes the nanoparticles in the solution, forms a very strong gradient to plant nanoparticles on the cells and covers the entire surface of the culture cup. In this regard, optimized magnetic plates with specified properties have been developed for magneto-ferection.

Highlights of the magnetic plates of O’sciences:

Suitable for all magnetoference reagents and all vascular variants for cell cultures (384-, 96-, 4, 24, 12, 6-hole tablets, 35, 60, 90 and 100 mm Petrie cups, T-25, T-75 and any other vials)

Can be easily treated and decontaminated by 70% ethanol

Can be used in incubators and with robots

Can be used at room temperature, 37 degrees C, 4 degrees Celsius, etc.

Compatible with cultural tablets of the most common suppliers

Solid, reusable, can be used for a long time.

Documents

Magnetic Plates Note

96-Magnets Plate MSDS

Super Magnetic Plate MSDS

Mega Magnetic Plate MSDS

application

OZ Biosciences Magnetic Plates.

Rosnano is a Russian company founded in 2011 by reorganizing the state corporation Russian Nanotechnology Corporation.

In 2020, the Russian government is included in the perimeter of the veb.RF Group Development Institutes.

type

corporation

foundation

2007

location

Russia: Moscow

Key figures

Sergey Kulikov (Chairman of the Board)

branch

Nanotechnology, Venture Investment

production

nanomaterial

equity

▲ 99 514 000 000 ₽ (2018)[1]

turnover

▲ 14 854 000 000 ₽ (2018)[1]

Operating profit

▲ 11 743 000 000 ₽ (2018)[1]

Net profit

▲ 5 636 000 000 ₽ (2018)[1]

assets

▲ 185 530 000 000 ₽ (2018)[1]

Parent company

The property

website

rusnano.com

Rosnano promotes the implementation of the state policy on the development of the nanoindustry by investing directly and through investment funds of nanotechnology in high-tech projects that ensure the development of new production facilities in the Russian Federation. The main areas of investment are nuclear medicine and medical instrumentation, innovative nanobiopharmaceuticals, nanoelectronics and photonics, nanocoating and surface modification, new materials, renewable energy and energy efficiency.

Rosnano’s 100% stake is state-owned. Thanks to Rosnano’s investments, about 97 plants and R-D centers have been opened in 37 regions of Russia.

The goals of creating nanotechnology infrastructure and implementing educational programs are carried out by the Foundation for Infrastructure and Educational Programs, also created as a result of the reorganization of the state corporation.

“To appoint Chubais Anatoly Borisovich as special representative of the President of the Russian Federation for relations with international organizations to achieve the goals of sustainable development,” reads president Vladimir Putin’s decree, which was published on the evening of December 4, 2020

Anatoly Chubais appointed Special Representative of the President for Relations with International Organizations

Vladimir Putin signed the decree “On the special representative of the President of the Russian Federation for relations with international organizations to achieve the goals of sustainable development.”

December 4, 2020 8:30 p.m.

The text of the Decree:

1. Appoint Chubais Anatoly Borisovich as special representative of the President of the Russian Federation for relations with international organizations to achieve the goals of sustainable development.

2. This decree comes into force from the day it is signed.

Face

Chubais Anatoly Borisovich

Material status

Published in sections: News, Documents

Published time: 4 Dec, 2020, 8:30 PM

Text version

What kind of special envoy is this? There are no such positions 👎

⚠️💉C100 deaths between the ages of 12 and 18 in the states in March.

For what purpose do injections but Cannes children? Why do children have to wear rags on their respiratory organs?

We see no purpose other than the outright genocide of the American population. Falsified U.S. statistics show official deaths from the unremarked “covid” virus in their age group

close to zero.

One more thing! Where did you share the usual flu in 2020?

🔹0.00001% 0-20 years

🔹0,0003% 21-40 years

🔹0.0035% 41-60 years

🔹0.02% 61-70 years

🔹0.1% 71-80 Years

🔹0.5% of 80 years

🔹Thsize in normal season from normal flu – 0.16%

Even with this lie, the child has no chance of dying from a cowid. They are almost equal to ZERO.

So we loudly ask U.S. officials 🇺🇸!

What exactly is the BENEFIT of children taking an experimental ‘vaccine’ of unknown composition from fake TV 📺 virus?

A small part of our reasons for high-profile questions 👇

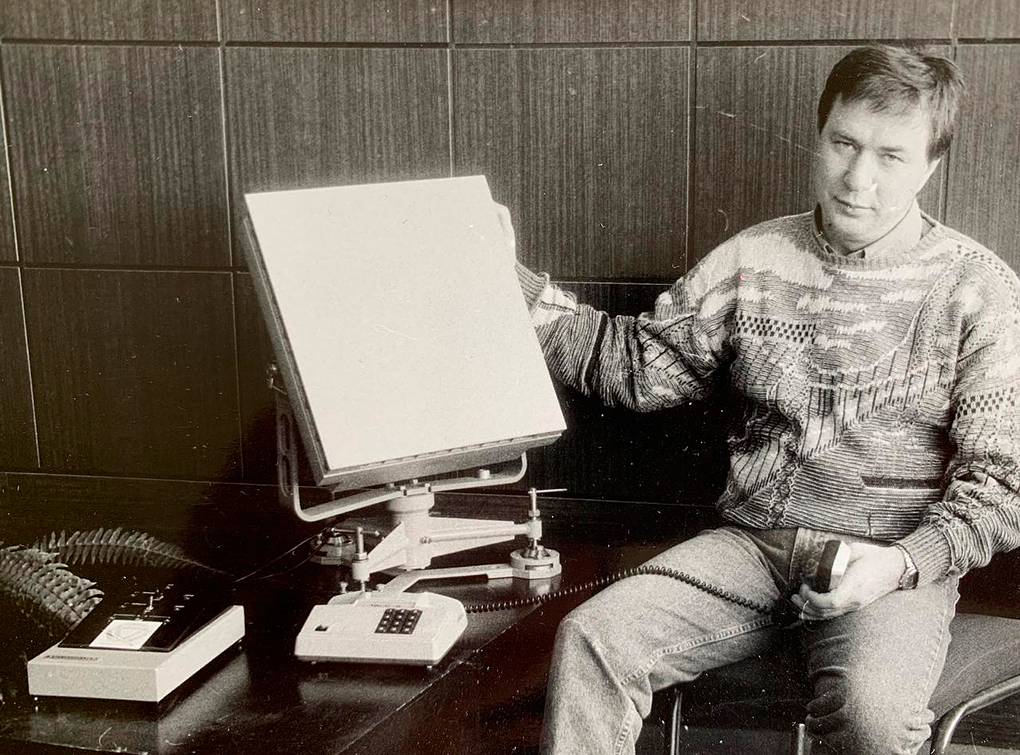

To the left of Bill Gates is former Soviet defense scientist Alexander Galitsky. 1997.

Alexander Galitsky, former Soviet defense officer of the NGO ELAS and current head of almaz Capital Partners venture fund, says:

“Since the mid-1980s, I have been preparing our response to Star Wars. We have developed various systems, including for the transmission and exchange of information between reconnaissance satellites.

It was a working model, and back in October 1990, we showed the Americans how IP packets, in other words, blocks of data, travel through space.

Those precipitated.

They were finally overwhelmed by a 22-layer polyamide board the size of a pack of cigarettes, which at some point I casually took out of my pocket. Nobody in the world has made such boards. “

Think about it – the vaunted Silicon Valley did not create anything of the kind that Soviet IT specialists created by 1990. And although many of us later moved there and admired the business processes in California, this does not negate the fact that the level of ingenuity of the Soviet Russian model of developing high scientific technologies was better.

Accordingly, with a reasonable approach to the modernization of the USSR, the same IT sector could become advanced in civilian life, as it was in higher positions.

We recommend finding and reading the entire interview. It is full of important information.

Galitsky was one of those in the scientific Soviet elite who immediately threw himself into the arms of the American market and began to cooperate with leading IT-schnicks, communicated with Gates and others. They believed in convergence (combining the socialist and capitalist systems), although it is obvious: the Soviet system collapsed. Nevertheless, thanks to Soviet science, a native of Zhitomir communicated with leading Western IT specialists, to

had excellent knowledge and

Operating time.

At the space communication station on the basis of a flat antenna-fared lattice, which transmitted information through IP protocol, 1990

Galitsky could and most likely handed over a number of high-tech U.S. (although this denies). Curiously, he talks about the interrogation in Washington, where he was made a written commitment not to work with the enemies of the United States, but at the same time he finished the right to work for the benefit of Russia.

In the 2000s he became actively involved in the technology of Russia, in particular the creation of electronic cash registers, the labeling of goods ❗️ Important point – he did not change the Russian passport to the American one, although he was persuaded by the U.S. consul himself.

Almaz Capital is an international venture fund that invests in software startups and SaaS. Almaz Capital is headquartered in Portola Valley, California, has an office in Berlin and representative offices in CEE countries. Almaz Capital’s managing partner is Alexander Galitsky.

https://en.wikipedia.org/wiki/Almaz_Capital

Interview pick:

Do you notice the closing of the deal?

The end of the entertaining cosmic nuances of Mr. Gusar Galitsky’s interview, fishing 🎣 with nudists in the Suez Canal on the yachts of Bezus and the Russian oligarch and other flights in a dream 💤 and in reality here 👇

https://telegra.ph/ApolloSoyuz-Test-Project-ASTP-20-07-08

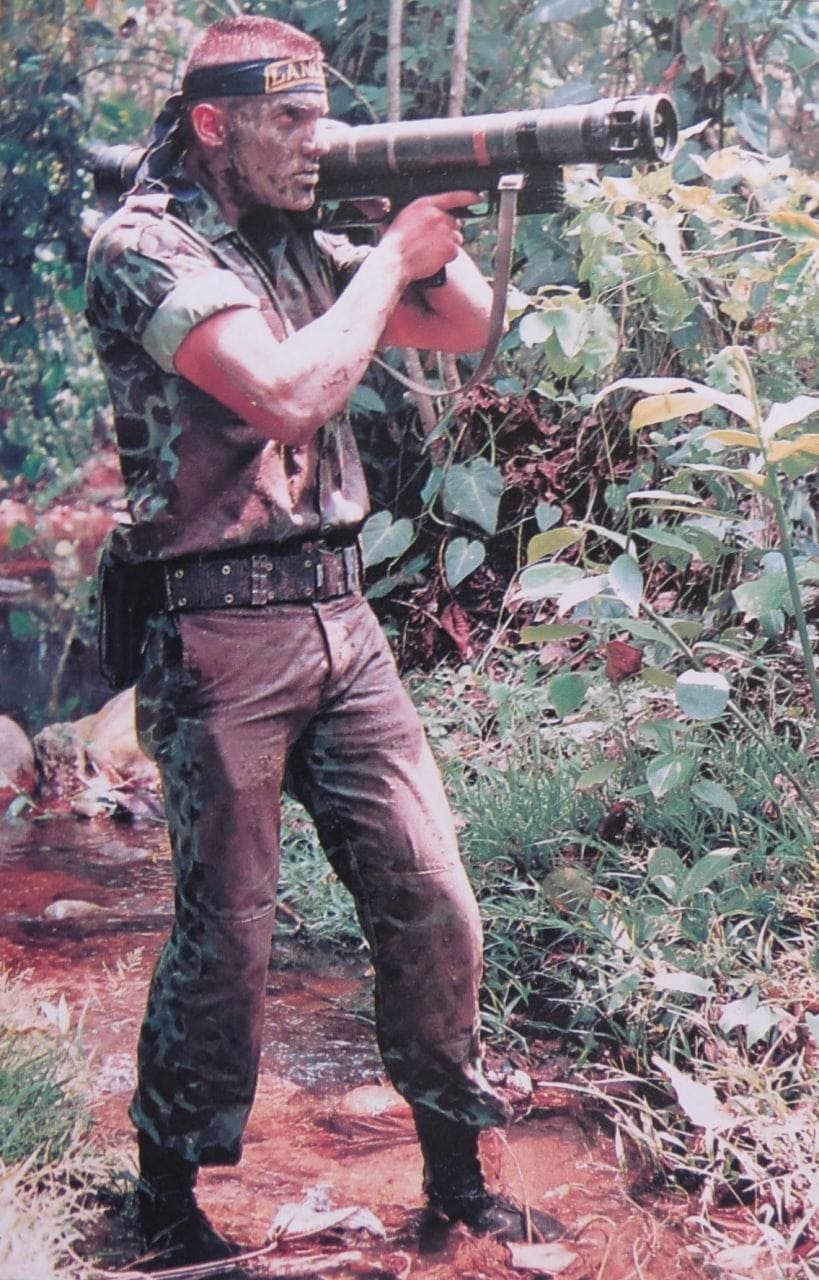

A Colombian soldier is targeted by a German grenade launcher during an operation against a communist drug cartel, 1992.

First RFID Patents

Mario V. Cardulo entered the first U.S. patent for an active rewritten RFID label on January 23, 1973. That same year, Charles Walton, a California entrepreneur, received a patent for a passive transponder used to open a door without a key. A map with a built-in transponder sent a signal to the receiver near the door. When the receiver detected the corresponding identification number recorded in the RFID label, the door opened. Walton has licensed this technology for Schlage and other companies.

The U.S. government has also worked on RFID systems. In the 1970s, the Department of Energy asked the National Laboratory in Los Alamos to develop a system to track nuclear materials. A group of scientists has developed the concept of placing tags in trucks, and readers on the gates of protected objects. The antenna at the gate activated the transponder on the truck, which transmits the ID along with other data, such as the driver’s ID. Driving through the gate of the mark in the truck is activated by the transmitter and transmits ID and other information, including the number of the driver’s license. This system was commercialized in the mid-1980s, when scientists from Los Alamos who worked on the project allowed the creation of a company to develop automated fare systems. These systems have become widely used on roads, bridges and tunnels around the world.

At the request of the Los Alamos Department of Agriculture, it also developed a passive RFID label to track the movement of cows. The problem was that cows were given hormones and medicine when they were sick. But it was difficult to trace that each cow got the right dose, or accidentally did not get it twice. Los Alamos developed a passive RFID system that used radio waves at a frequency of 125 kHz. The label in a special glass capsule could have been implanted under the cow’s skin. The label received energy from the reader and simply reflected back the modulated signal using the so-called reverse scattering. This system is still used to track cows around the world. Low-frequency transponders were also embedded in the cards used to access buildings.

Over time, companies began commercial use of 125 kHz systems and then expanded the spectrum to treble (13.56 MHz), which was unregulated and not used in most countries of the world. The high frequency allowed for an increase in the range and speed of data transmission. Companies, especially European ones, have begun using this frequency to track reusable containers and other fixed assets. Today, RFID 13.56 MHz systems are used for access control, in payment systems (Mobile Speedpass) and in contactless smart cards. They are also used as an anti-car device in cars. The reader in the steering column reads a passive RFID label in the plastic case of the key handle. If the reader does not read the identification number for which it is programmed to search, the car will not start.

In the early 1990s, IBM engineers developed and patented the ultra-high-frequency (UHF) RFID system. UHF offered a longer reading range (up to 20 feet under favorable conditions) and a higher data rate. IBM has launched several early pilot projects with Wal-Mart, but has never offered this technology for commercial use. Due to financial problems in the mid-1990s, IBM sold its patents to Intermec, a bar coding provider. Intermec’s RFID systems have been installed in many different applications, from warehouse accounting to agriculture. But at that time the technology was quite expensive because of low sales volume and lack of open international standards.

The development of UHF RFID was boosted in 1999 when Uniform Code Council, EAN International, Procter and Gamble and Gillette financed the creation of the Auto-ID Center at the Massachusetts Institute of Technology. Two professors, David Brock and Sandja Sharma, conducted research on the possibility of placing cheap RFID tags on all products to track them in the supply chain. Their idea was to write down only the serial number for cheaper tags (a simple microchip that stores very little information would cost much less to produce than more complex chips with more memory). The data on the chip associated with the serial number would be stored in a database that would be available via the Internet.

Sharma and Brock have essentially changed the way RFID is used in the supply chain. Previously, the tags were a mobile database that contained information about the goods or container in which they were transported. Sharma and Brock turned RFID into network technology by connecting objects to the Internet through a label. For the business, this was an important change, because now the manufacturer allowed the business partner to automatically trace when the goods came out of the factory or from the warehouse, and the retailer could automatically inform the manufacturer when the goods arrived.

Between 1999 and 2003, the Auto-ID Center supported more than a hundred large end-user companies, as well as the U.S. Department of Defense and many key RFID vendors. The Centre has opened research laboratories in Australia,

Switzerland, Japan and China. He developed two protocols (Class 1 and Class 2), an EPC (Electronic Product Code) standard, and an online architecture to find data tied to the Internet RFID label. The technology was licensed by the Uniform Code Council (UCC) in 2003, and then Uniform Code Council established EPCglobal as a joint venture with EAN to commercialize EPC technology. The Auto-ID Center closed in October 2003 and all of its research work was transferred to Auto-ID Labs.

Several of the world’s largest retailers (Albertsons, Metro, Target, Tesco, Wal-Mart) and the U.S. Department of Defense said they plan to use UPC technology to track goods in the supply chain. Pharmaceutical, tire, defense and other industries also plan to use this technology. In December 2004, EPCglobal adopted the second-generation Gen2 standard, paving the way for the widespread use of RFID technology.

Human nervous system, extracted by two medical students in 1925. It took 1,500 hours for the entire recovery process. There are only 4 such exhibits in the world.

Merlin is happy with such a good end to the week)

ᗰᖇ. ᑭᖇᝪᗞᑌᑕᗴᖇ В+